Ideal For

- Analysis of metallic abrasive quality

- Manufacturers of abrasive

- Consumers of abrasive

- Laboratory and field testing

Applications

- Foundry and Forge

- Metallurgy

- Transportation

- Energy sector

- Construction

- Fabrication

Since it was patented in 1947 the Ervin Test Machine has been widely used to benchmark abrasive quality, and embodies the innovative pioneering spirit of our founder John F Ervin. Through standardised testing, it is able to compare the durability and transmitted energy of different abrasives.

The abrasive that transmits the most energy to the work piece with the highest durability should be both the highest productivity and the lowest cost. The easily portable machine allows on-site testing using actual abrasive from the shot blasting operation.

In 1947, the founder of Ervin, John F Ervin conceived, built and patented the Ervin Shot Testing Machine to maintain

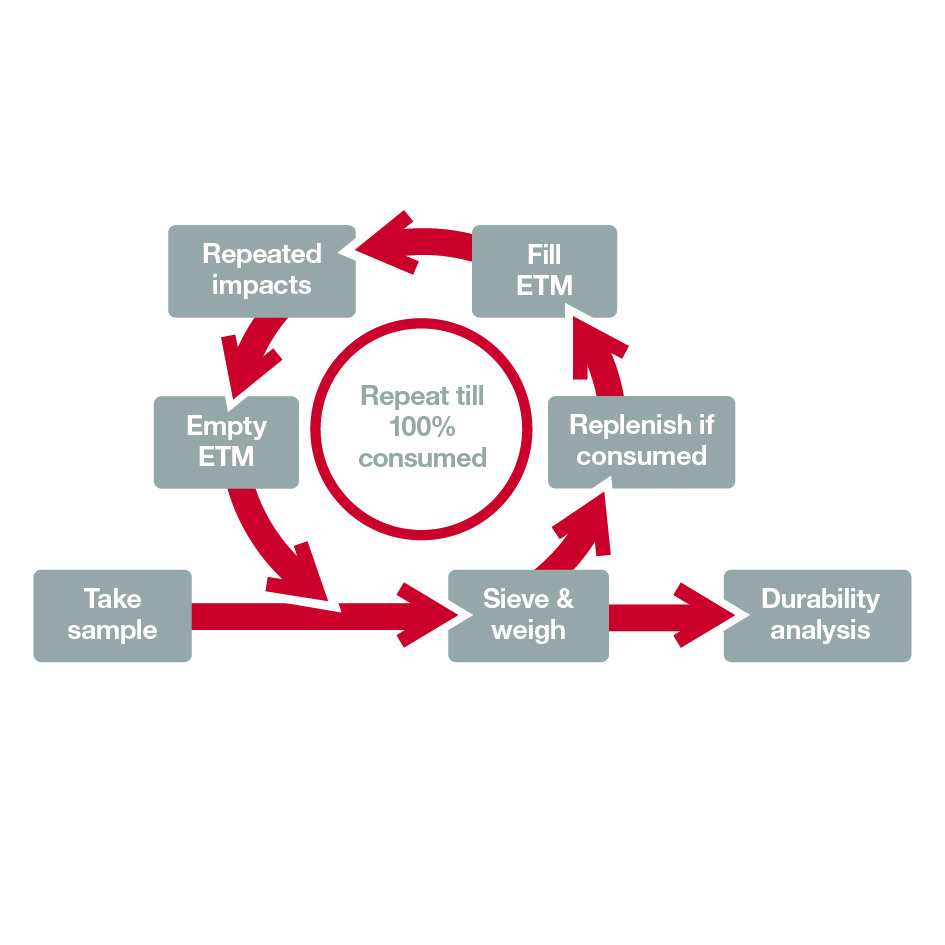

his own products’ high standard of quality. The Ervin Test Machine (ETM), is used to benchmark output, through SAE J445 and ISO 11125-9, as well as to perform comparative abrasive testing of similar grades. It is recognised widely as the world standard for comparing abrasive quality. Basic operation involves the propulsion of a sieved and weighed sample of abrasive using a rotating centrifugal wheel to accelerate the particles. The sample is thrown against a hard anvil surface, collected and returned to the wheel, and the process repeated, subjecting the material to repeated impacts. The ETM is emptied, the sample sieved and weighed, and lost material is replenished. This process is repeated until 100% of the original sample has been consumed, and its durability can be calculated.

The ETM is still used today by all Ervin plants, and most abrasive manufacturers across the world. The machine is specially designed to be portable, allowing on site tests with abrasive taken directly from the shot blasting operation.

Abrasive specifications help define the properties that control their value. In laboratory conditions, an ETM allows different samples of abrasive to be compared. The machine measures both Durability (abrasive life) and Transmitted Energy (impact energy), which are the two key measures of the value and quality. These tests are a practical way of demonstrating the effect of abrasive quality in a shot blasting operation.

Higher quality abrasives transmit the greatest amount of energy to the work piece with the longest life, producing the most cost-effective operation. A real life shot blasting operation is a complex system with a high number of variables that cannot be replicated. The unique design of the ETM allows a standardised simplified test of abrasive quality to be performed and gives an ideal introduction to abrasive quality.

The ETM is a great indicator of comparative quality, which should be followed by a comparative trial in the real life shot blasting operation to find the ideal abrasive solution.

Our sales office can guide you through the quotation process. Please call +49 2324 904 980, visit the contact page or complete the form below.

Select the application type you’d like solutions for

{{ steps_labels.step_2.text }}

{{ steps_labels.step_3.text }}

{{ steps_labels.step_4.text }}

Contact our experienced sales team to discuss your requirements.

Contact