- +49 30 400 37846

-

English

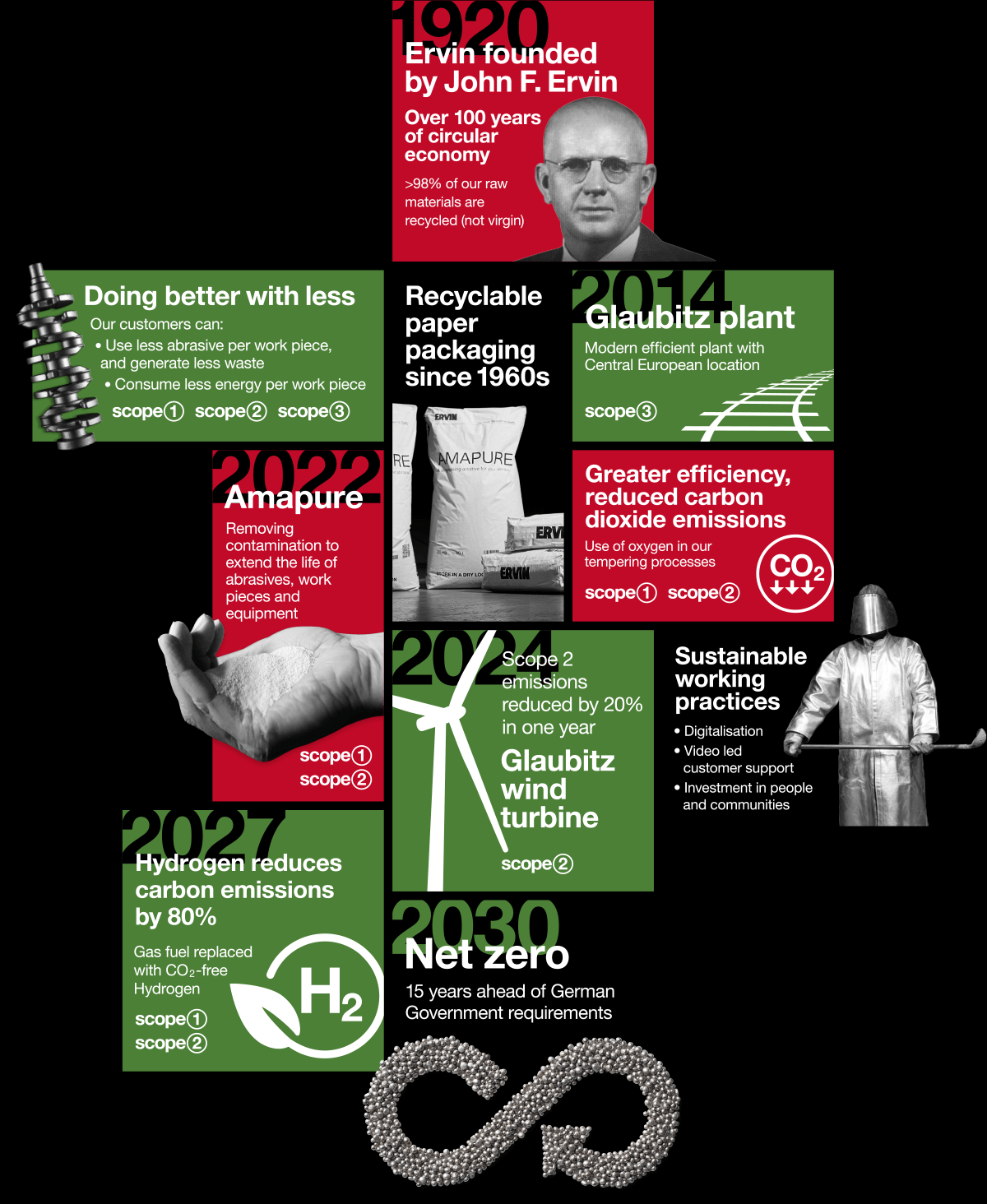

Our Past

At Ervin, sustainability is not a new idea; John F Ervin started our company in the early 1920s with an innovative concept for recycling scrap steel to improve productivity, reduce resource consumption and reduce waste in his customers’ blasting process, creating our own circular economy. His desire to do better with less has been handed down through his descendants who still lead our company. 100+ years of family ownership has given us the freedom to take the right decisions for the long-term, meaning our sales, manufacturing and growth plans have been and always will be sustainable.

Our Present

Our unique high-quality production process using >98% recycled raw materials produces the highest possible quality steel shot and grit abrasives. The high durability and transmitted energy of our shot and grit means our customers use less abrasive per work piece and generate less waste, improving the sustainability of their blasting operations.

The tight quality control of size, hardness and microstructure of our abrasives means they deliver greater cleaning power, reducing blasting costs, including energy usage.

The Ervin technical team helps customers find the best abrasive to achieve their desired clean and surface profile, giving coatings the best possible corrosion resistance and extended service life. Many customers who have switched to Ervin abrasive report a reduction in rework which reduces costs and improves relationships with their customers.

In 2022, Ervin launched a new mineral degreasing product, Amapure which absorbs any oil and grease from the operating mix, extending the life of the abrasive, work pieces and equipment, whilst reducing waste and cost for the customer.

Our Future

Energy consumption and energy sources are an area of increasing focus across all manufacturing industries. Ervin uses electric arc furnaces to melt the scrap steel which gives a much lower carbon emission level than for the manufacture of crude steel and we have been developing alternative renewable and greener energy sources.

A new wind turbine will provide electricity to our manufacturing plants and reduce our scope 2 carbon emissions by 20% from 2024 onwards. We are using oxygen to reduce our scope 1 and scope 2 emissions and are partners in the Central Germany Hydrogen Network enabling us to replace natural gas with hydrogen from 2027. Compared with 2023, our manufacturing carbon emissions will reduce by at least 80% within 4 years. We are committed to achieving a “net zero carbon emissions” position by 2030.

Ervin has been the only steel abrasive manufacturer to supply standard material in recyclable paper bags for many years and we continue to work closely with leading suppliers to further reduce or completely eliminate non-recyclable packaging materials.

Across our business, we are exploring more sustainable ways of working, from an increase in Electric Vehicles (EV) company cars to increased use of video conferencing, both internally and with customers. We have an ongoing programme of information digitalisation, to reduce paper and improve accuracy. Ervin continues to invest heavily in its people and communities.

As we begin the second century of our company’s history, our commitment to sustainability remains strong; we have a strong programme mapped out and are always looking for opportunities to do better with less. We believe John F Ervin would be very proud of the company’s ability to sustain his vision and excited by our future plans.

Let’s Talk

Our sales team can tell you more about our company. Please call +49 30 400 37846, visit the contact page or complete the form below.